nolting history

Decades of Innovation. Generations of Craft.

Nolting’s legacy is stitched with passion, precision, and a deep commitment to empowering quilters everywhere.

Our Story: The Roots of Longarm Innovation

Longarm quilting began in the 1960s and ’70s, when inventive quilters started modifying commercial sewing machines to handle larger projects. By mounting machines on wheeled carriages, they introduced a new method—moving the machine over stationary fabric. As quilt sizes and batting thickness increased, so did the need for machines with more reach and height. But technical challenges slowed progress.

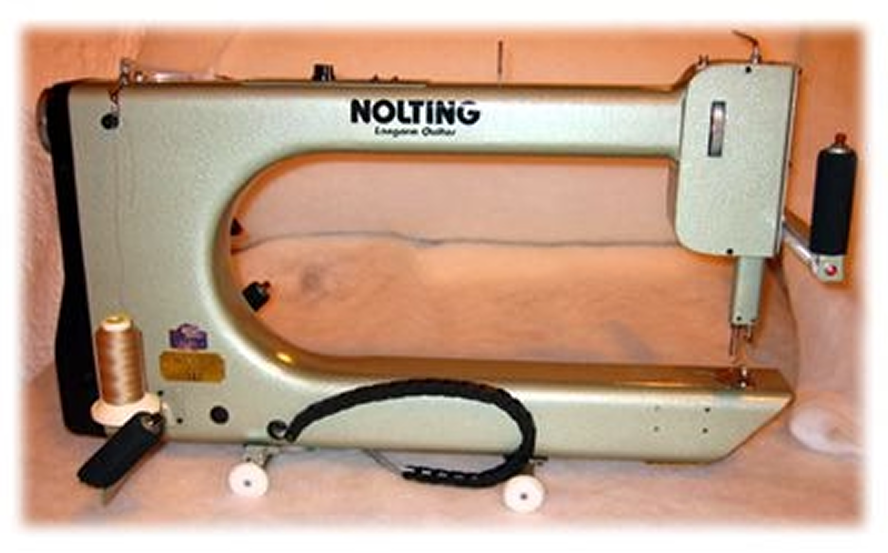

Enter Fred Nolting—a skilled mechanic with a passion for innovation. In the 1970s, while working in a sewing factory in Missouri, Fred built a prototype of a high-throat, long-reach quilting machine. Though it was rudimentary, it worked—and it sparked a revolution. By the 1980s, Fred had turned his side project into Nolting Manufacturing, making longarm quilting more accessible and powerful.

Fred’s breakthroughs—like front and rear handles, the hopping foot, and eventually the first computer-driven and stitch-regulated longarm machine—transformed the industry. From launching the Hobby Quilter and Fun Quilter to refining professional-grade tools, Nolting helped shape the modern quilting landscape.

Today, Nolting remains a trusted name in quilting, known for unmatched craftsmanship, innovation, and commitment to empowering quilters everywhere.

Engineered to Last. Built to Perform. Backed by Experts.

In a world of disposable products, Nolting longarm quilting machines stand as a symbol of lasting quality and craftsmanship. Designed for professional-grade use, these machines are built to handle thousands of quilts without wearing out. Every component is thoughtfully engineered for durability, operator-adjustable, and easy to maintain—because quilters don’t have time for downtime. Our machines and frames are not only rugged but refined, reflecting decades of innovation and a deep understanding of what serious quilters need to thrive.

At Nolting, we manufacture everything that makes our machines unique—from sawing and welding to full assembly and quality testing by in-house quilters. No machine leaves the factory without being stitched on and fine-tuned to perfection. And when you need help, you’ll speak directly with the technicians who build the machines—not someone reading a script. Our nationwide network of knowledgeable dealers and expert factory support ensures that whether you’re troubleshooting or just have a question, you’ll always get the guidance you need, fast.

We believe premium quality should be practical. That’s why Nolting offers the highest craftsmanship across all sizes and features—without chasing gimmicks. From thoughtful threading to easy setup and maintenance, every detail is refined to make your experience smooth and stress-free. And no matter your budget, you can feel secure knowing you're getting best-in-class quality at every price point—machines designed to last, support that truly serves, and a brand that respects your craft.

Proudly American Made – And Always Happy to Welcome You

Nolting machines and frames are built in the heart of America with unmatched craftsmanship and durability. If you're near our Eastern Iowa factory, stop by and see where quality comes to life—or visit us at quilt shows around the world. We’d love to meet you and help in any way we can.

Nolting Features: Purpose-Built for Serious Quilters

Every Nolting Longarm quilting machine is engineered with precision, power, and ease in mind. Here's what makes it stand out:

Lightweight yet strong 3/16" aluminum body (24"+) ensures fluid motion and long-term durability

Internal vibration-dampening foam and sealed bearings deliver a quiet, smooth sewing experience

Gear belt drive and enclosed track wheels provide precise, low-maintenance performance

Ergonomic vertical handles reduce fatigue and stay out of your line of sight

Focusable front/rear laser stylus and ruler-friendly hopping foot for accurate quilting

Fluorescent light with optional blacklight enhances visibility for creative work

Standard 110V plug—no special wiring required

Variable speed controller and optional Intellistitch® stitch regulator for custom stitch control

Compatible with Hartley Fence® and other popular accessories

Two-piece steel table fits through tight spaces and comes in various lengths

Easy-access bobbin area and roller lift for batting adjustment without repositioning

Cord chain system keeps power cords off the floor for safe, uninterrupted quilting

Optional hydraulic lift legs and track locks for ergonomic and precise stitching

What’s Included

5-year warranty

Bobbin winder, 10 bobbins, 10 needles, 5 starter patterns

Printed manuals and direct access to factory tech support